A BID FOR BETTER AT THE DAWN OF 3D PRINTING

He was a software guy, not a machinist. Not yet, anyway.

But one afternoon at auction, he got into a spirited bidding war on a machine. $250 later he had his very own vintage micro-lathe. It was exactly what he needed to enable him to begin making a real difference in the dawning desktop 3D printer movement.

It was 2009 and Rick Pollack owned one of the first commercially available desktop 3D printers. The machines were built with laser-cut plywood and, though they were a lot of fun to build, did not work very well. At that time, the extruder components on the machines were unreliable at best. Pollack recalls that if someone actually managed to successfully 3D print an object it was cause to break out the champagne.

The online community that had sprung up around this new technology was filled with conversations about how to get the problematic extruders to successfully melt and evenly dispense the plastic filament. This fledgling technology, brimming with possibility, but lacking in consistency, had Pollack wondering how he could do this better.

Pollack began using his “new” micro-lathe to prototype extruders, and after numerous attempts and variations found a design that worked. Pollack’s print quality greatly improved and his extruders were consistent. Successful prints were now an expectation on his desktop 3D printer and no longer an exception.

Pollack leveraged his knowledge of online communities to communicate with other 3D printer users who were desperately in need of reliable extruders and ready to try his design. For the first several months, Pollack made parts by hand during the day, and provided technical support and took orders online by night. And so MakerGear began – with Pollack at his lathe, helping other 3D printer users get their machines up and extruding smoothly.

As MakerGear took hold, it developed a reputation for providing high-quality precision parts backed up by excellent customer service. From the beginning, MakerGear’s solid reputation for quality and support was paving its way forward into this growing industry.

FROM HAND-MADE EXTRUDERS TO ROCK-SOLID MACHINES

It didn’t take long for Pollack to begin designing and constructing his own desktop 3D printers to sell to his ever-growing, loyal MakerGear customers. His first offering was a MakerGear RepRap kit, but always on the pursuit for better, he soon set up shop, laser-cutting frames and assembling plywood-frame printers at his home.

In 2011 Pollack launched the MakerGear Mosaic (also known as the M1), which received great reviews. His desire to constantly improve created a culture of perpetual innovation within MakerGear, raising the bar for what was possible in the realm of 3D printing.

While continuing to run MakerGear, Pollack enrolled in a daily CNC machining class. After a couple of months, he had developed the confidence he needed to bid on an industrial CNC machine at an online auction. As if buying an expensive CNC machine sight unseen from across the country wasn’t stressful enough, Pollack also realized that it was too big to fit through the shop doors. Six weeks later it arrived during a downpour on a flatbed truck. After removing a few parts, it fit through the doors.

This marked a pivotal moment when MakerGear evolved from maker to manufacturer. The CNC equipment provided the opportunity to produce 3D printers on MakerGear’s timeline and to MakerGear's specifications. The company’s mission was to create a durable product that could offer as much utility in a machine shop as it did in an office, studio or classroom.

MakerGear released its third 3D printer – the MakerGear M2 – in April 2012. Unlike its plywood predecessors, the M2 was constructed from fabricated steel and machined aluminum. Rock solid and built to last for the long haul, the machine was a delight to customers, both for its construction and consistency. This feedback further emboldened MakerGear’s commitment to using stainless steel frames and precision-machined components.

MakerGear’s original workhorse, the M2 has become a worldwide success. It has received numerous user awards around the globe for its product quality and reliability. It took top-honors in 3D Hubs’ Annual 3D Printer Guide for three consecutive years, and was rated the Number 1 Desktop 3D Printer in the World in 2017.

M3-SE & M3-ID: THE NEXT GENERATION

While its original workhorse was garnering top accolades, MakerGear was chomping at the bit to introduce its next generation of 3D printers. The MakerGear M3-SE and MakerGear M3-ID were unveiled at the RAPID + TCT 3D Printing and Additive Manufacturing show in Pittsburgh in May 2017.

The M3 series offers advancements built on MakerGear’s precision-machined systems and designs, emphasizing performance and enabling continuous, 24/7 operation. With features like True-Leveling™, wifi connectivity, wireless control and an integrated user interface, the M3 series has made it easier than ever to leverage the advantages of 3D printing.

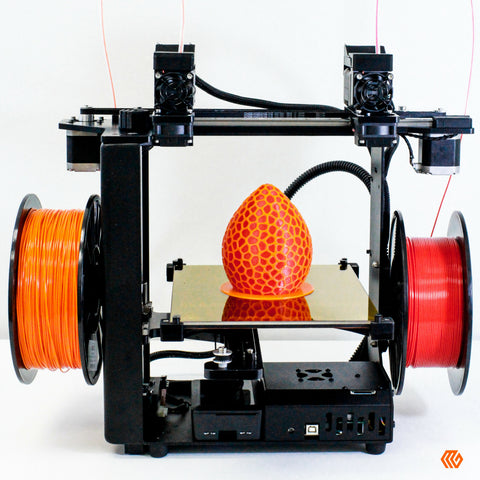

The M3-ID offers a fast, efficient and reliable solution to the growing demand for multi-material and soluble-material 3D printing. With its independent dual extruders, it has enabled businesses and professionals to double their production speed for single-material prints. For professionals new to 3D printing or for those looking to keep it simple, the M3-SE has made it easier and more cost-effective than ever to harvest the benefits of professional 3D printing.

MAKERGEAR’S INDUSTRIAL 3D PRINTER: THE ULTRA ONE

Since its introduction, the M3 series has further strengthened MakerGear’s reputation as a manufacturer of professional-grade 3D printers that are reliable, durable and adaptable.

But what if the company could take its unwavering commitment to innovation and excellence even further?

In September of 2018, less than 10 years after it had introduced its plywood-frame Mosaic, MakerGear unveiled its Ultra One industrial 3D printer at the International Manufacturing Technology Show (IMTS) in Chicago.

Shrouded in riveted sheet metal, the MakerGear Ultra One combines industrial reliability with consumer-driven flexibility. It features independent direct-drive dual extruders, an assisted bed-leveling system with automatic compensation, and extensive connectivity options powered by an onboard print management system. With its 16” by 14” by 13” build volume and fully sealed enclosure, the Ultra One marked MakerGear’s entry into industrial 3D printing.

COMMITMENT TO CUSTOMERS & COMMUNITY

Today, MakerGear printers can be found in all 50 states and over 75 countries. Rick Pollack’s commitment to the community in which it all started has kept MakerGear’s headquarters, production and tech support in Beachwood, Ohio. Many of the components used in MakerGear 3D printers are manufactured within a 30-minute drive of Cleveland, and, with its extensive investment in local manufacturing, MakerGear has brought tens of millions of dollars into Ohio.

While much has changed since Pollack’s initial investment in a vintage lathe in 2009, MakerGear continues to embody his vision as a company that never lets anything stand in its way of creating machines that set the precedent for precision and durability. A company built on thoughtfully responding to the changing needs of its customers, MakerGear continues to push the boundaries of innovation and craft rock-solid machines. Amidst the numerous advances and seismic shifts that have occurred in desktop 3D printing, MakerGear printers remain as ready-to-run and built-to-last as ever.

MORE ABOUT OUR FOUNDER