Bowden vs. Direct Drive

In the early days of desktop 3D printing, manufacturers were looking for ways to speed up the printing process. One technology that was released was a Bowden extruder, which removed the weight of the extruder motor from the fast-moving hot end by having a stationary motor push the filament through a long tube to the hot end. While this seems to work adequately for rigid materials like PLA, materials with any flex to them do not perform well with this extruder system. One tactic employed to deal with this lack of rigidity was to use 2.85 mm filament rather than 1.75 mm, which means that each micro-step of the extruder pushes out more than 2.5 times as much material—definitely not a good thing.

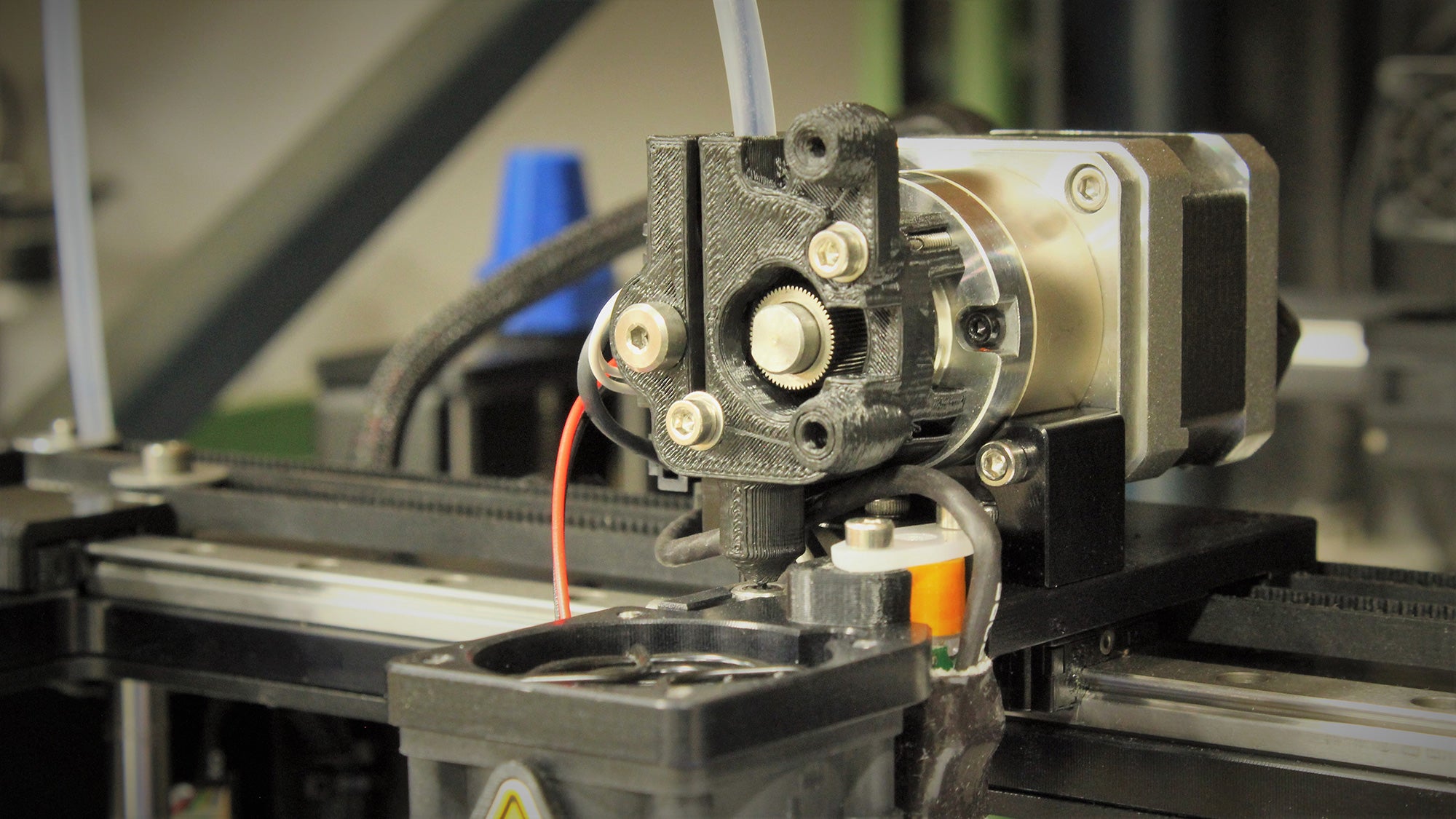

While reducing the mobile mass of the extruder system is beneficial, the reduced control that comes with the Bowden system has negative effects on print quality and reliability. Because MakerGear has used all metal frames and linear rails for motion control since 2012, our printers have been able to support the extra mass that comes with a direct drive system while also edging the competition on speed.